What is a release agent ?

To mold the synthetic resin , synthetic rubber molding occasion , the processing applied to the mold agent. As the oil in the pan coating , produced on the mold surface a protective film to prevent the molding material adhering to the mold .

Release agent for use in the automobile industry for example, tires , bumpers , gaskets , etc., sporting goods for the golf club head , tennis racket , fishing rod , etc., it is used on the products shaping .

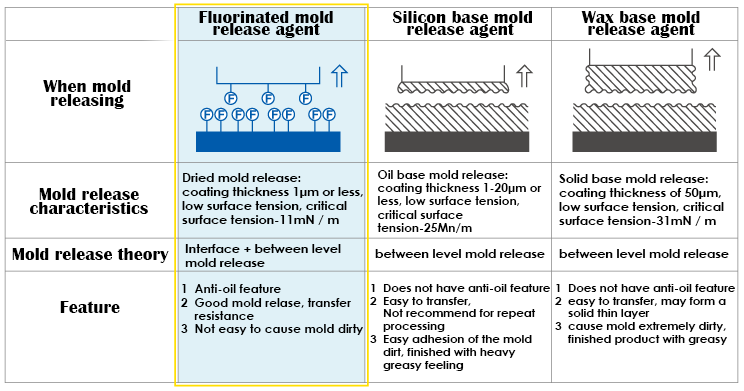

Release agent of various types and characteristics

- fluorine release agent -See [ fluorine release agent product characteristics ]

- Silicon ( Si ) release agent -With silicone oil lubrication, mold release resistance and is widely used. Disadvantage is oily film has fluidity , easy to make produce molds dirt , easy to transfer to the molded product surface, does not apply on the areas of need for secondary machining and precision molding applications . Furthermore, it’s not suitable for the electrical parts molding , caused by electrical adverse result on the parts. .

- wax release agent –

Thick coating thickness will bring dirty mold, mold releasability will be decreased , it’s not recommended . The transfer to the molded article is relatively simple cleaning of the wax on the final product, so the use of the coating to the molded for the finished product . - Surfactant release agent -Poor stripping but the price is cheap, easy to use in the molding material and release on low value products molding.