Taiwan’s only professional industry started from fluorspar into the production of fluorine fingerprint-proof product.

Supply anti-fingerprint material related industries in the world

Brand new technical support to different industries and integrate ODM, OEM and other resource.

Anti-Fingerprint Coating

|

|||||||||||||||||||||||||||||||||||||||||

| Test items | TF series | ||

|

C |

W |

||

|

Operation process |

Vapor deposition |

SPRAY |

|

|

Contact angle |

water |

116° |

115° |

|

Hexadecane |

68° |

67° |

|

|

Drop angle |

water |

8° |

8° |

|

Hexadecane |

6° |

6° |

|

|

Steel wool durability testing |

5000times |

3000times |

|

|

Eraser durability testing |

Pass |

Pass |

|

|

Salt spray test |

116° |

113° |

|

|

Dynamic friction coefficient |

0.030 |

0.030 |

|

Excellent properties

- brushing the surface of the agent can reduce the adhesion of fingerprints and various stains , and has adhered stains can be easily removed . Because of strong adhesion coating , after wiping it with tulle and the coating still worked well.

- the surface of the dynamic friction coefficient (μ = 0.09 or less) lower dry surface lubrication can be obtained .

- On the glass, plastic , metal material with the chemical binding occurs as drying at room temperature to form a high adhesion & High hardness ( pencil hardness 3H ~ 7H) transparent antifouling coating .

- brushing the plastic and other non- glass & metal material , the first coat of primer specific for the pre- attached treatment, which can form the same high adhesion & High hardness antifouling coating .

- TF antifouling coating film thickness of about 2-6nm film ,the original appearances of substrate kept .

- Meanwhile, the coating film will be kept to prevent the appearance of deterioration .

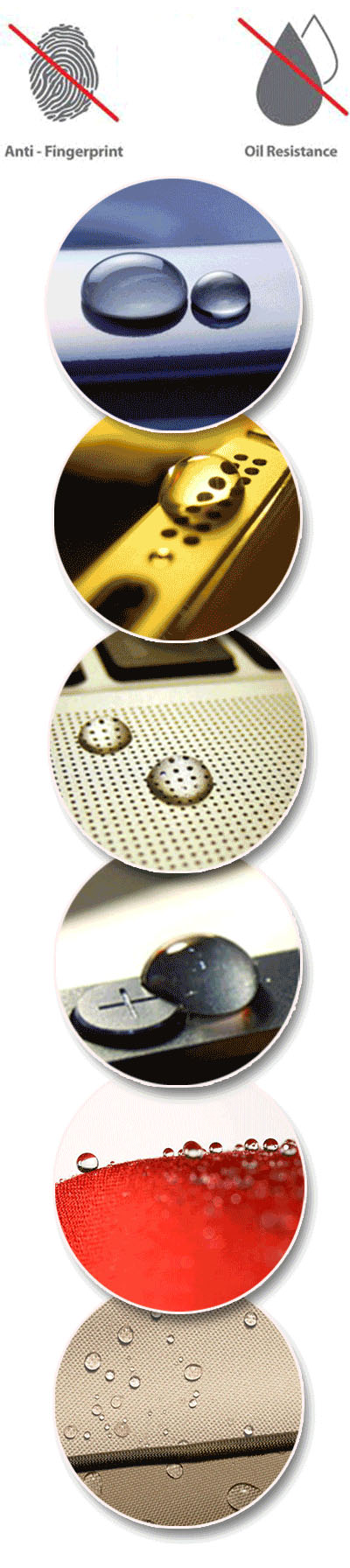

TF use examples

- Mobile phones, game consoles and other display

- Computer Keyboard

- Contact Sensor switch part

- Prevent precious stones, jewels attached of the oil and dirt.

- Car body coating and antifouling coating of aluminum wheels

- faucet metal parts

- Prevent fingerprints on the glass door